Product classification

Vertical rubber injection molding machine

Key words:

Huahan Intelligence

Classification:

Product Description

Dalian Huahan Intelligent Equipment Co., Ltd. mainly produces: Dalian rubber machinery, flat vulcanizing machine, rubber injection molding machine, vertical rubber injection machine, conveyor belt vulcanizing machine. As a professional rubber plate vulcanizer manufacturer, our rubber plate vulcanizer price and rubber injection molding machine price are very competitive in the market. If you want to know which is good for flat vulcanizing machine, you may as well come to us and have a look. The company was established in 2018 and is composed of professional R & D, production and sales teams. The company has more than 20 years of experience in the production of rubber equipment, and Chinese and Korean people have always been to assist customers in producing high-quality rubber products. Our company has an independent research and development department, is committed to the improvement of quality and technology, and has obtained a number of technical patents.

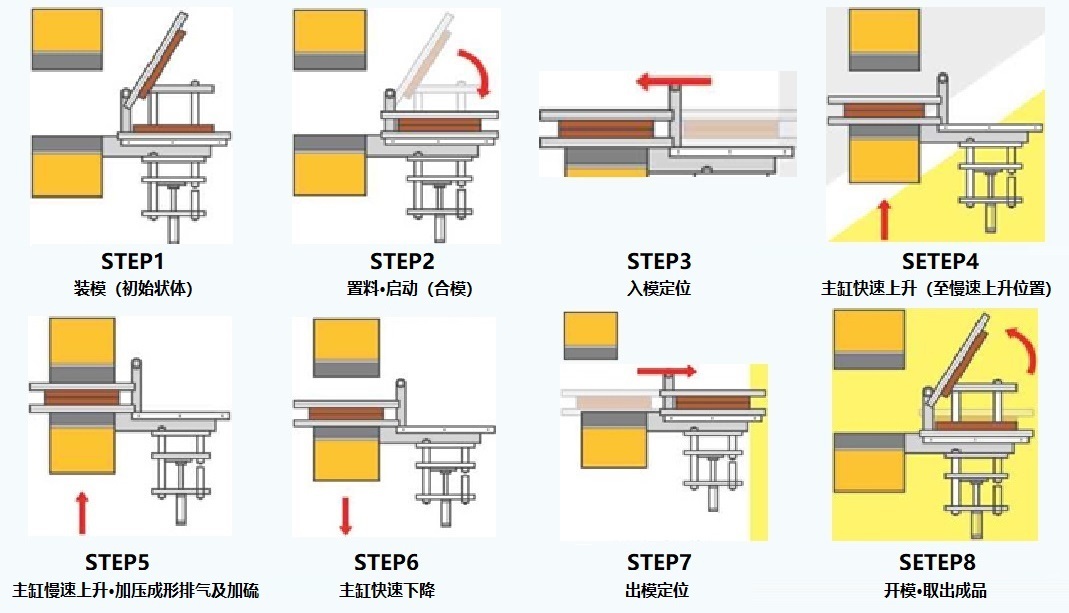

Mold opening method

Product Features/FEATURES

♦Prevent dead material residue

♦Rubber replacement is easy not to waste

♦Applicable to all kinds of rubber raw materials

Mold correction

♦The use of optical ruler to adjust the thickness of the mold

Heating system

♦Using SSR solid state relay, heating fast without overtemperature

Access formwork, front top formwork

♦Special isolation device design to prevent wear of hot plate and inner/outer template

♦Front top mold is divided into 2RT/3RT/4RT

hydraulic circuit design

♦The specific pressure and specific flow hydraulic system designed to facilitate the adjustment of pressure and speed

SPECIFICATION

Model | Work surface (mm) | Motor (horsepower) | output (tons) | Piston diameter (mm) | Travel (mm) | Injection volume (mm) | Screw diameter (mm) |

MODEL | PLATFORM (mm) | MOTOR (HP) | OUTPUT (Tons) | CYLINDER DIAMETER (mm) | STROKE (Mm) | INJECTION VOLUME (C.C) | SCREW DIAMETER (MM) |

RI-20. | 550x550 600 x600 | 15 x 6P | 200 | Φ350 | 450 | 1600~2000 | Φ44 |

RI-25 | 600x650 | 20 x 6P | 250 | Φ400 | 450 | 2000~2500 | Φ44 |

RI-30 | 650x650 | 20 x 6P | 300 | Φ450 | 450 | 2500~3000 | Φ50 |

Model |

|

| Injection cylinder diameter (mm) |

| Maximum pressure (Kgf/cm²) | Machine size (length, width, height meter) | Weight (kg) |

MODEL |

|

| INJECTION CYLINDER DIAMETER (mm) |

| UNIT PRESSURE (Kgf/cm²) | MACHINE (M) | WEIGHT (KG) |

RI-20. |

|

| Φ77 |

| 210 | 2.7x1.6x2.3 | 7500 |

RI-25 |

|

| Φ85 |

| 210 | 2.8x1.7x4.2 | 9500 |

RI-30 |

|

| Φ90 |

| 210 | 2.8x1.8x4.5 | 10500 |

|

|

|

|

|

|

|

|

We can customize the products for you according to your needs. Please fill in the form below and we will contact you in time!