Product classification

Horizontal rubber injection molding machine

Key words:

Huahan Intelligence

Classification:

Product Description

Dalian Huahan Intelligent Equipment Co., Ltd. mainly produces: Dalian rubber machinery, flat vulcanizing machine, rubber injection molding machine, vertical rubber injection machine, conveyor belt vulcanizing machine. As a professional rubber plate vulcanizer manufacturer, our rubber plate vulcanizer price and rubber injection molding machine price are very competitive in the market. If you want to know which is good for flat vulcanizing machine, you may as well come to us and have a look. The company was established in 2018 and is composed of professional R & D, production and sales teams. The company has more than 20 years of experience in the production of rubber equipment, and Chinese and Korean people have always been to assist customers in producing high-quality rubber products. Our company has an independent research and development department, is committed to the improvement of quality and technology, and has obtained a number of technical patents.

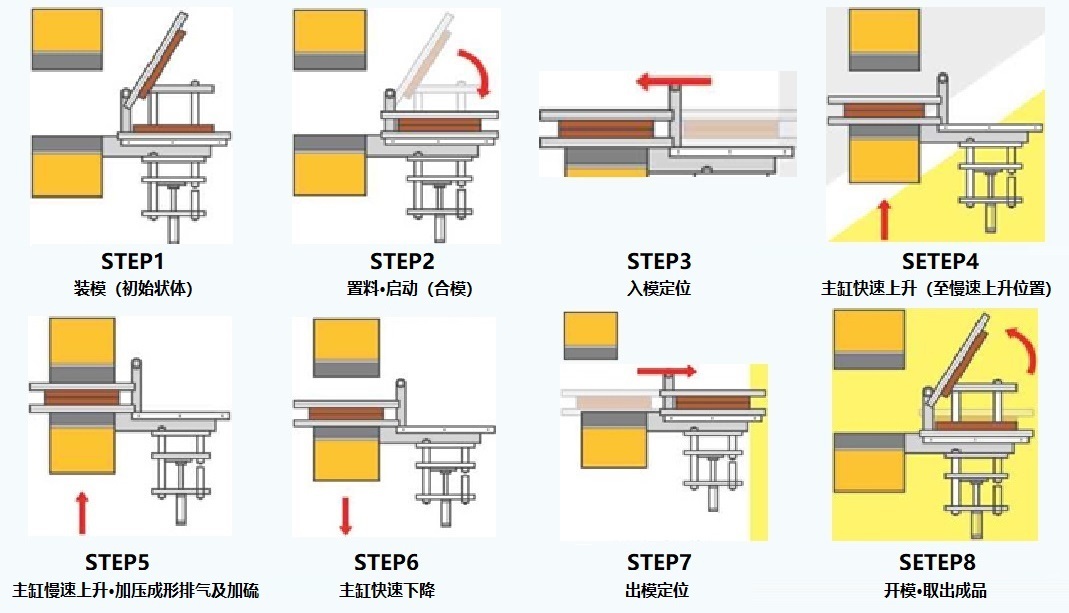

Mold opening method

Product Features/FEATURES

Machine features

♦Low-voltage protection mould

♦Rising-Descent multi-stage control

♦Pressure stable, accurate and quiet

♦Temperature accurate, accurate exhaust•Low noise

♦Multi-function, man-machine interface/PLCControl

injection system

♦Multi-stage pressure, speed, injection volume control

♦Digital Injection Volume Control

♦Durable injection rod■With anti-reflux function, characterized by precise temperature control

Feed system

♦Effectively remove air bubbles and install a device to prevent the return of the material

Control unit

♦Full-featured flow control display

♦User-friendly software programming

♦Multi-group Row Data Storage

♦Full unit fault detection function

Standard/SPECIFICATION

Mechanical | Work surface (mm) | Motor (horsepower) | output (tons) | Piston diameter (mm) | Travel (mm) | Injection volume (mm) | Screw diameter (mm) |

MODEL | PLATFORM (mm) | MOTOR (HP) | OUTPUT (Tons) | CYLINDER DIAMETER (mm) | STROKE (Mm) | INJECTION VOLUME (C.C) | SCREW DIAMETER (MM) |

INJ-100 | 460x460 | 10 | 100 | Φ250 | 450 | 1000 | Φ44 |

INJ-200 | 550x550 | 15 | 200 | Φ350 | 450 | 1600~2000 | Φ44 |

INJ-300 | 600x600 | 20 | 300 | Φ450 | 450 | 2500~3000 | Φ44 |

INJ-400 | 700x700 | 20 | 400 | Φ500 | 450 | 3000~6000 | Φ50 |

INJ-500 | 700x750 | 30 | 500 | Φ560 | 450 | 4000~12000 | Φ70 |

Model | Storage barrel diameter (mm) | Injection cylinder diameter (mm) | Maximum pressure (Kgf/cm²) | Machine size (length, width, height meter) | Weight (kg) | ||

MODEL | MATERIAL CYLINDER DIAMETER (mm) | INJECTION CYLINDER DIAMETER (Mm) | UNIT PRESSURE (Kgf/cm²) | MACHINE (M) | WEIGHT (KG) | ||

INJ-100 | Φ65 | Φ200 |

| 210 | 2.2x1.6x2.3 | 4500 | |

INJ-200 | Φ75 | Φ225 |

| 210 | 2.5x1.8x2.5 | 6500 | |

INJ-300 | Φ90 | Φ275 |

| 210 | 4.1x2.6x2.8 | 9000 | |

INJ-400 | Φ120 | Φ300 |

| 210 | 4.1x2.4x2.8 | 11000 | |

INJ-500 | Φ130 | Φ330 |

| 210 | 5.1x2.5x3.4 | 13000 |

We can customize the products for you according to your needs. Please fill in the form below and we will contact you in time!